Hunting for "Unicorns" | Dynaflow: Building "AI + Lights-out Laboratories" to Cultivate "Robot Chemists"

Published Time:

2025-06-27

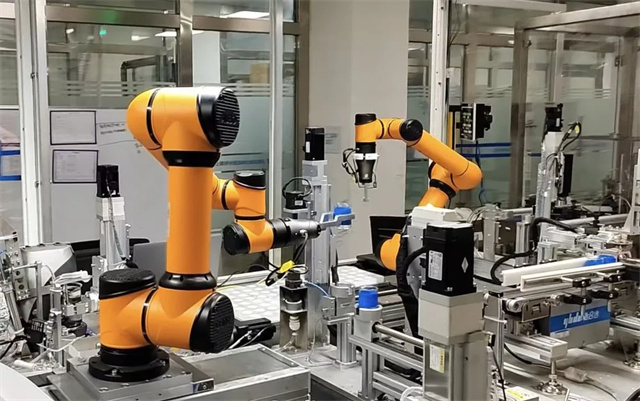

Based on instrumented robots and AI-enabled instruments, we will build an AI + Lights-out Laboratories platform scheduling system in the future. This system will act as a 'brain', coordinating all instruments to meet various experimental needs, reshaping the scientific research paradigm and industrial ecosystem.

Enabling robots to conduct experiments and record data around the clock, replacing researchers in various complex or dangerous manual experiments... This once science fiction scenario has become a reality at Beijing Dynaflow Lab Solution Co., Ltd. (hereinafter referred to as "Dynaflow"). As a national high-tech enterprise and a specialized and new enterprise, Dynaflow's full-lifecycle "AI + Lights-out Laboratories" solution has now covered the fields of chemical engineering, energy, and food, bringing about a leap in laboratory efficiency while also promising to cultivate "robot chemists" with high-quality data, making up for the shortcomings of high-end scientific instruments in China's scientific and technological innovation.

"A Day Equals a Year" Laboratories Achieve Efficiency Leap

"AI + Lights-out Laboratories working one day is equivalent to a frontline researcher working one year." Dynaflow Chairman Chi Haipeng told reporters that AI + Lights-out Laboratories can automatically complete a series of tasks according to preset technical routes, including sample processing, operation of experimental instruments, transportation of reagents and consumables, environmental control, data analysis, and report generation, helping scientists and laboratory personnel free their hands and effectively improve the innovation ability of researchers.

Taking the most basic weighing work as an example, the weighing process seems simple, but manual operation is both time-consuming and inaccurate. In AI + Lights-out Laboratories, after repeatedly weighing dozens or hundreds of times, the automatic weighing robot learns and evolves by itself, making the weighing more accurate and the results more stable. This can not only be applied to the detection of common samples but also to the weighing of dangerous objects, greatly reducing the risk of manual operation.

More importantly, due to the absence of human factors, the data produced by AI + Lights-out Laboratories is high-quality data. "High-quality data is the oil of the future AI era." Chi Haipeng said that therefore, the core competitiveness of AI + Lights-out Laboratories consists of three parts: AI (algorithm management platform, intelligent robots, etc.), unmanned laboratories (automatic control equipment and advanced experimental instruments, etc.), and the generation of high-quality data.

"Chemistry is a process of repeated trial and error, so the efficiency of AI + Lights-out Laboratories is far higher than that of manual operation." Chi Haipeng believes that people quickly tire when doing repetitive work, but "robot chemists" can do various formulas indefinitely and can quickly form models for prediction. Another advantage is that, for example, while humans need 50 data points to predict a curve, AI may only need 5 to make an accurate prediction.

Therefore, AI + Lights-out Laboratories shows great application prospects in experimental processes with high repetition, strict precision requirements, high danger, or special environmental needs.

"Chemistry, materials, new energy, and food are the four areas we are focusing on." Chi Haipeng introduced that, taking the new material research and development field as an example, AI + Lights-out Laboratories has realized functions such as autonomous selection and self-optimization of experimental paths, automatic formula trial and error combination, fully automatic performance testing, rapid curve generation, and rapid generation of high-quality data. Currently, Dynaflow's "AI + Lights-out Laboratories" solution has been applied to fine chemical engineering, petrochemical engineering, materials science, new energy batteries, and daily chemical product detection systems, such as high-throughput, highly toxic liquid full-process automated detection systems in the petrochemical industry, high-viscosity liquid sample full-process automated detection systems in the daily chemical industry, and artificial graphite particle size full-process automated detection systems in the new energy industry. In the future, it is expected to be applied to education, medical, biological, physical, and electronic fields.

The artificial graphite particle size automatic detection system designed and built by Dynaflow for Shangtai Technology.

Continuous Progress and Breakthroughs Showcase China's Innovative Strength

"About 6 years ago, Unilever, a multinational company, launched a global unmanned laboratory project, preparing to fully implement unmanned replacement in 107 factories worldwide. They looked for many companies in the United States and China to undertake this project, and ultimately, Dynaflow was the first to achieve unmanned laboratories at Unilever's Hefei factory." Speaking of Dynaflow's shampoo and shower gel detection project on Unilever's Hefei production line, Chi Haipeng is quite proud, and this is also a reflection of China's innovative strength in the field of laboratory automation.

In 2011, Chi Haipeng, who had worked for Thermo Fisher Scientific, a global leader in the laboratory industry, for 7 years, left his job to start his own business and formed Dynaflow with several like-minded friends.

"We initially started with the design and construction of laboratories, from Beijing Changping Future Science City to Zhongguancun Science City, China Resources Life Science Park, and Yizhuang Development Zone. Dynaflow has participated in many projects." Chi Haipeng told reporters that in this process, many problems were discovered, such as the lack of intelligence in laboratories and the relatively backward construction methods, resulting in uncontrollable quality. "So we decided to develop in two directions at that time: one is the smart laboratory, and the other is the prefabricated laboratory. We transformed the original engineering into modular products, automated production in the factory, and rapid assembly. These two directions have continued to be developed and iterated, and now they have evolved into AI + Lights-out Laboratories."

Today, from the preliminary design of the laboratory to the prefabricated production of laboratory modules, to on-site automated assembly, and subsequent maintenance and management of the laboratory, Dynaflow can provide a full-lifecycle "AI + Lights-out Laboratories" solution.

Addressing the "Biggest Shortcoming" Targeting High-End Scientific Instruments

On May 30, Beijing released the "Action Plan for the Innovative Development of High-end Scientific Instruments," which proposes to promote "AI+" to empower instrument innovation, especially planning for the construction of dark laboratories. This is a key deployment for China's scientific and technological self-reliance and self-improvement, and it is also a great benefit for Dynaflow.

"The domestication rate of China's scientific research instruments is less than 5%, and the domestication rate of large optical instruments is even less than 0.2%. In fact, the biggest "stuck neck" technology is in the field of scientific research instruments." Chi Haipeng sighed, so Dynaflow will also innovate and develop in the field of high-end scientific instruments in the future, "One direction is instrumented robots, and the other is AI-based instrument equipment."

In fact, relying on its rich experience in the laboratory field and the needs of numerous customers, Dynaflow has already carried out the research and development and production of a series of AI + Lights-out Laboratories interdisciplinary instrument equipment. In 2022, Dynaflow and Qingdao University jointly established a postdoctoral research station, mainly engaged in research in robotics, optics, virology, and medicine. It has completed the research and development of instruments and equipment such as the PPMI photon-directed precision microbial detection instrument (the world's first online air virus detection device), portable microfluidic rapid detection equipment, deep ultraviolet virus rapid disinfection machine, and microgravity random positioning instrument (the only one in production in China), and has the capacity for industrial production. Among them, the "microgravity random positioning instrument" was selected for the "Top 100 New Technologies and New Products List" of the 2024 Zhongguancun Forum.

"Based on instrumented robots and AI-based instrument equipment, in the future, we will also build an AI + Lights-out Laboratories platform scheduling system, like a "brain," where all instrument equipment can be coordinated and scheduled to meet various experimental needs, reshaping the scientific research paradigm and industrial ecosystem." Chi Haipeng is full of expectations for the future.

Hot Articles

Share to