Modular Battery Factory

As a modular battery factory solution provider, Dynaflow adopts a standardized design, production, and installation MEP solution. With BIM and modularization as its core, the factory is divided into three major categories of standard modular units: branch line modules, main line modules, and equipment modules. This achieves an assembly rate of over 80%, shortening the construction period by 9 months. Production utilizes a fully automated industrial line for prefabrication of electromechanical pipeline modules, assigning QR codes to modules throughout the entire chain to ensure traceability.

Reduced On-site Labor

Construction Period Shortened

Cost Reduction

Noise Reduction

Reduced Solid Waste

Reduced Carbon Dioxide Emissions

Technical Advantages

Efficiency Advantages

With the prefabricated modular approach, the project cycle is only 8 months, and a single unit takes 6.5 months, 3 months ahead of the user's plan.

Cost Performance

In the dry cleanroom implementation phase, the prefabricated modular approach is estimated to save 8-10% in costs.

Quality, Safety, and Environment

Modular battery factories significantly reduce high-altitude, cutting, and other hazardous operations on-site. Noise is controlled at 60dB, reducing exhaust gas and dust by over 70%, solid waste and carbon emissions by over 90%.

Intelligent Operation and Maintenance

Integrating intelligent cloud services and digital twin technology to provide post-construction 3D visualization management for factory operation and maintenance, safeguarding future operations.

Procurement Advantages

Factory prefabrication enables global high-quality procurement, ensuring high-quality and cost-effective products. The Morocco factory helps reduce costs and shorten construction times.

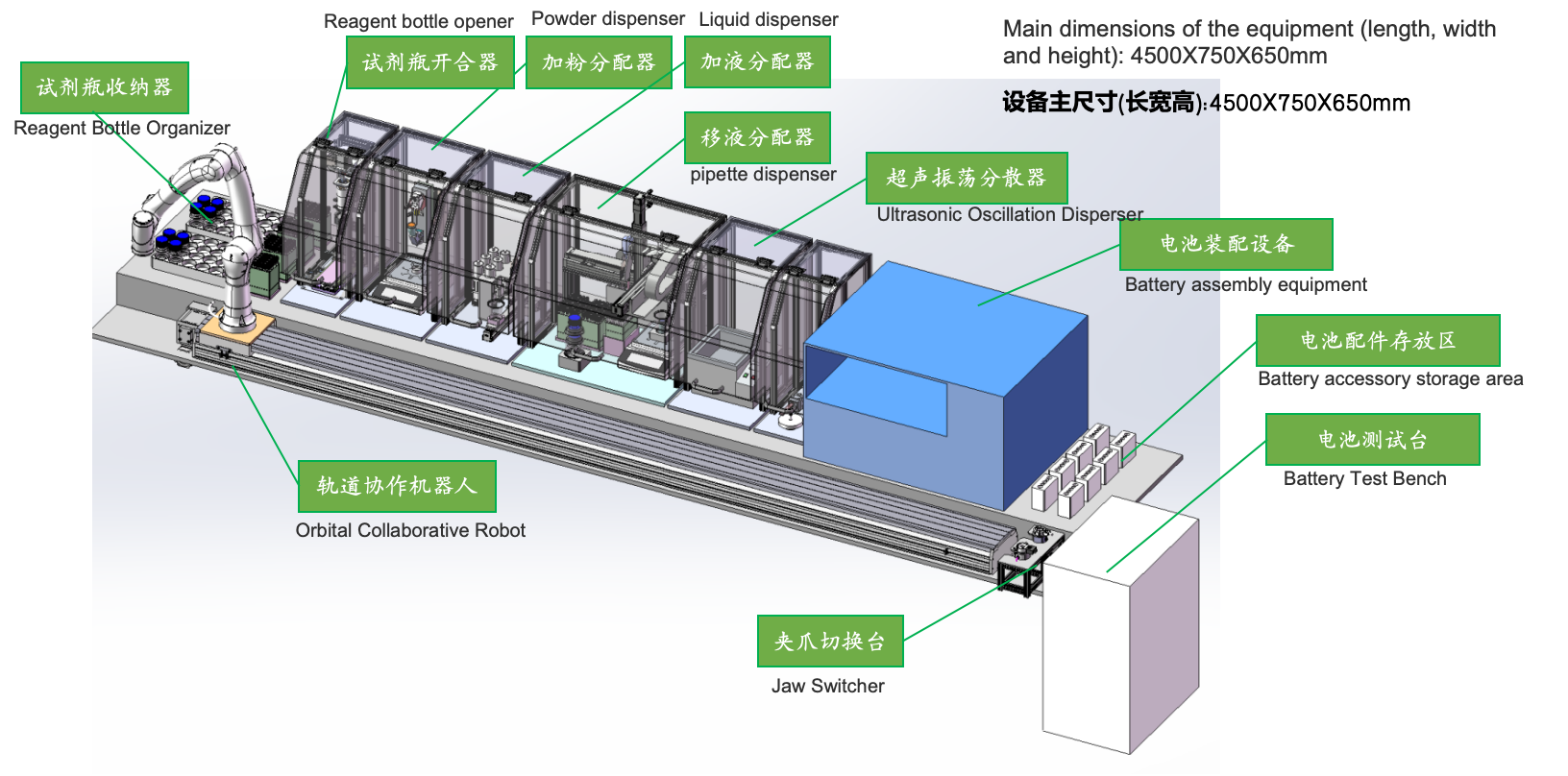

Automated QC Production Line

Dynaflow provides an automated quality control line for battery factories, utilizing robots to integrate battery testing processes and equipment, significantly improving testing efficiency.

Case Study:

Malvern MS3000, Daily Capacity: Automatically completes testing of 2,500 graphite samples per day (20 hours).

Automated Process:

After the sample is delivered to the designated location, all pre-processing, testing, and data uploading tasks are completed by the robot.

Sample Identification:

The robot automatically identifies and performs different tests accordingly.

LIMS Integration:

The robot integrates with the customer's LIMS (Laboratory Information Management System) to automatically evaluate test results. In case of data anomalies, the system automatically retains the sample for further review.

Intelligent Operation and Maintenance System

Equipment Status Collection

3D Visualization Monitoring

Intelligent Analysis and Location

Based on basic BIM design, integrating all factory monitoring data, it can intelligently analyze and predict equipment operating status, issue real-time warnings and alarms, making factory operation more efficient, stable, and safe.

Intelligent maintenance plans are scheduled based on parameters such as the cumulative operating time of intelligent monitoring equipment, equipment life, and maintenance experience, reducing emergency repairs caused by sudden equipment failures and extending equipment life.

Collects equipment status such as vibration, temperature, speed, and current, and monitors and analyzes equipment operating status in real-time based on a predictive maintenance model to predict equipment failures in advance and avoid downtime risks caused by equipment failures.