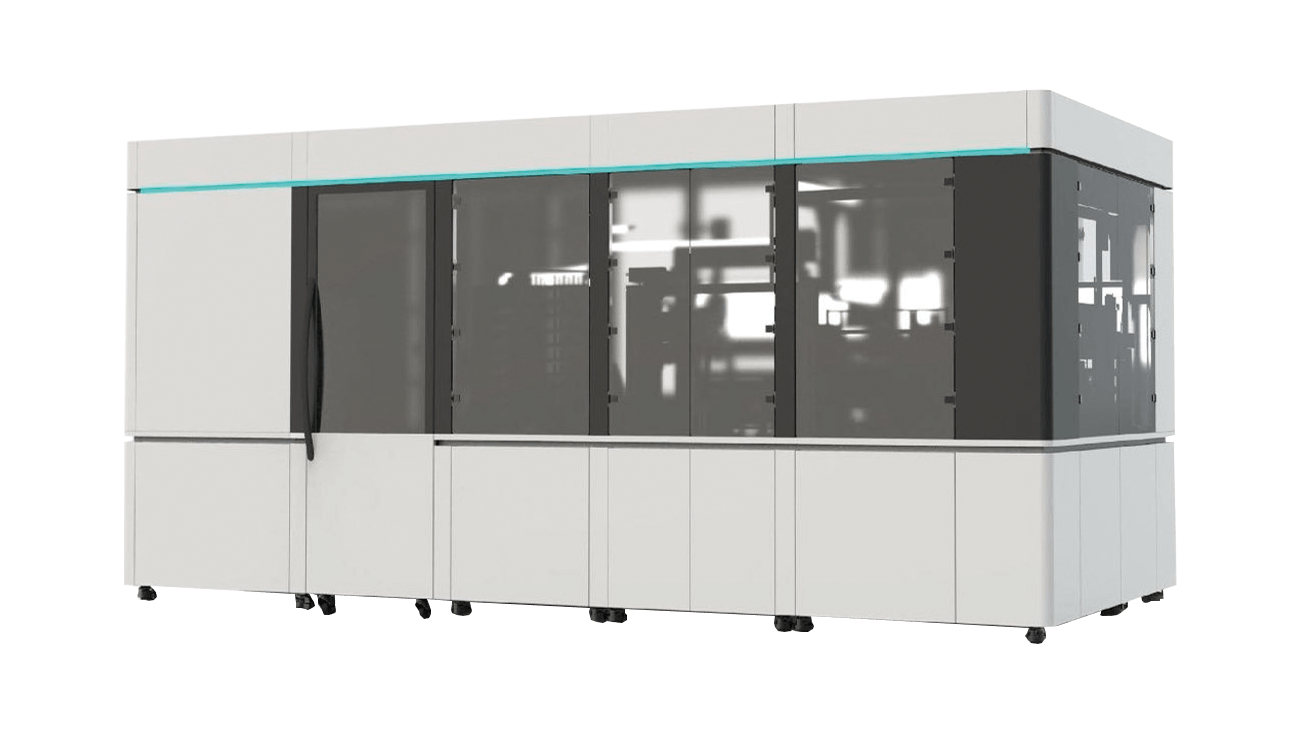

Liquid-based cytology slide staining workstation

Keywords:

Product Description

A multi-axis mechanism works with a robot to perform operations such as pipetting and sample transfer, and to perform slide preparation, staining, and sealing on the collected cell samples. The staining procedure follows the Papanicolaou staining method to ensure staining effect. It supports the input and output buffering of sample tubes, sedimentation chambers, and related consumables. Corresponding input and output buffer zones are designed for specific consumables to achieve automated cell sample slide preparation and staining.

Product Features

- Processes approximately 1500 samples per day.

- Identifies input samples and labels output samples for sample traceability, reducing human error.

- The overall structure is semi-enclosed, equipped with system access control opening detection, improving safety.

- External HMI allows selection of process flow and issuance of task commands, with a user-friendly interface.

Product Applications

- Suitable for clinical testing and cell biology.

Product Parameters

|

Product Name |

Liquid-based Cytology Slide Preparation and Staining Workstation |

|

Testing Items |

Slide preparation, Papanicolaou staining, and sealing of collected liquid-based cytology samples. |

|

Material Buffer Capacity |

240 sets |

|

Sample Processing Quantity per Hour |

180+ |

|

Experimental Consumables |

Cell preservation solution (sample tubes), sedimentation chambers, cover glasses, disposable pipette tips, etc. |

|

Cleanliness Level |

Suitable for Class 10,000 cleanroom |

|

Protection Level |

The system meets the requirements of IP20, and partial areas meet IP65/IP67. |

|

Number of Robotic Arm Axes |

6 |

|

Robotic Arm Load Capacity |

6kg |

|

Disinfection Method |

UV sterilization irradiation, 75% alcohol wipe disinfection |

|

Maximum Power |

2000W |

|

Operating Voltage |

220V |

|

Frequency |

50Hz |

|

Weight |

2000kg |

|

External Dimensions |

4200*2200*2300mm |

Related Products

Catalyst Crush Strength Test Workstation

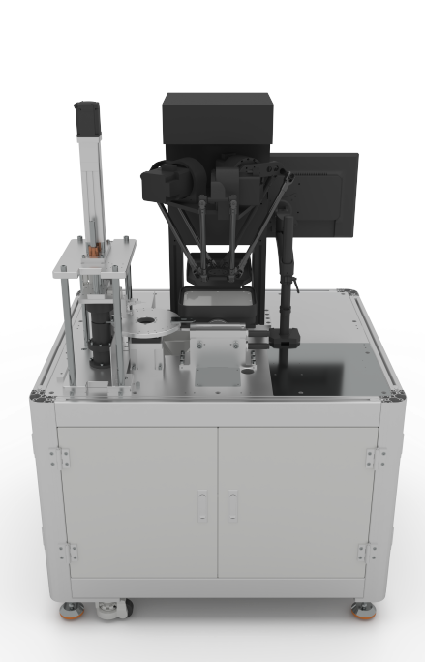

The catalyst crush strength testing workstation integrates parallel robot and visual analysis technologies. This equipment is used for the detection of size and crush strength in the catalyst production line, and analyzes the data simultaneously. The equipment uses a vision camera to automatically identify the coordinates of the catalyst. A parallel manipulator automatically grasps the catalyst, performs a secondary inspection of its appearance, and then sends it to a servo pressure testing device. The computer simultaneously stores the crush data curve of each catalyst.

PH automatic analysis workstation

The automated pH analysis workstation integrates collaborative robots, AGV intelligent logistics, and cloud control technology. The workstation uses an advanced automated execution system (such as industrial robots, precision grippers, high-precision diaphragm pumps, servo cylinders, etc.) to achieve unmanned, fully automated pH analysis.

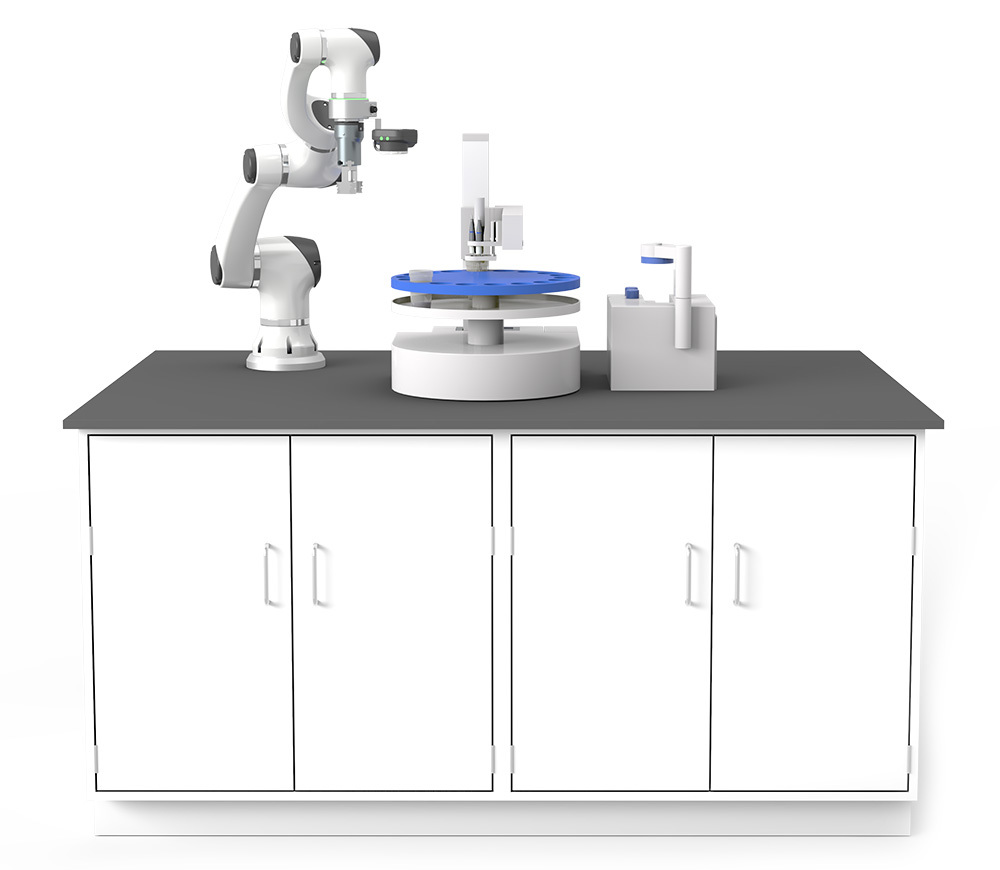

Liquid Precision Weighing Robot DNAW-W600

The liquid precision weighing robot includes a robotic arm, a liquid suction device, a lid-opening manipulator, a precision electronic balance, an ultrasonic distance sensor, and other auxiliary components. It is equipped with intelligent control devices such as an industrial computer, a servo driver, and a small programmable logic controller. It integrates dedicated management software deployed on both the industrial control computer and the user's computer. Users can set the weighing weight and weighing accuracy through the computer, and the robot will automatically complete the weighing work according to the requirements.

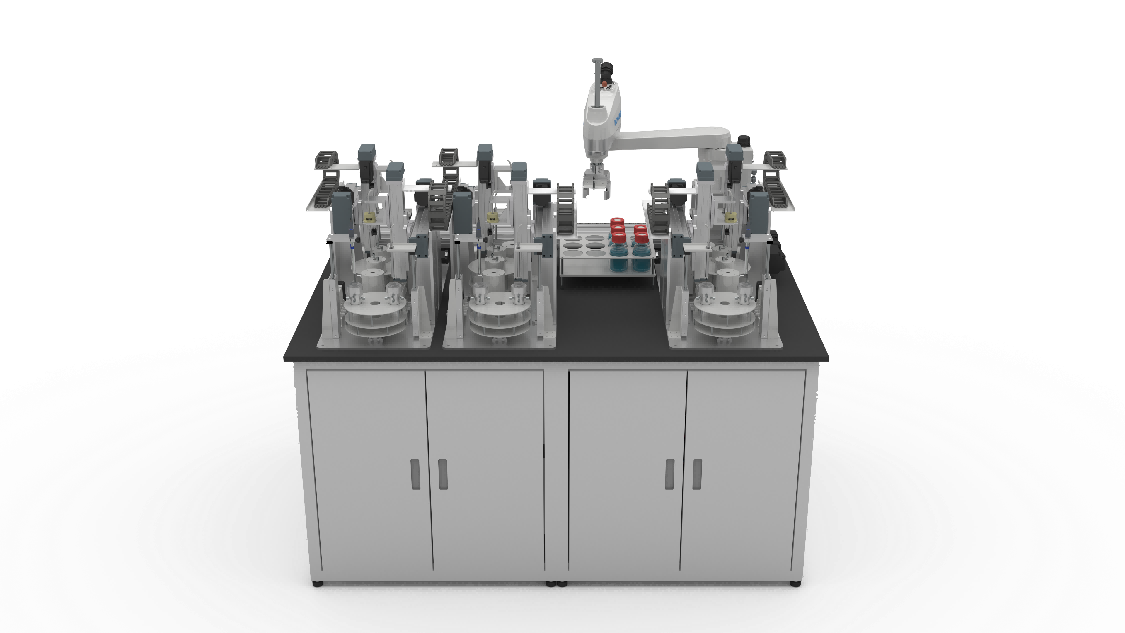

Titration automatic detection robot DNAT-W240

The automatic titration detection robot consists of a titration device, a liquid adding device, an automatic sampler robot, etc. The titration device includes a measurement module and interfaces to other units related to titration control; the automatic sampler robot includes an automatic titration manipulator and a sample tray suitable for high-throughput titration applications. The robot, working with a potentiometric titrator, can automatically load and unload samples and complete the entire detection process. The potentiometric titrator can connect to the DynaWise management system to read and upload test data. The automatic titration detection robot can be equipped with various pretreatment modules as needed.

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!