Catalyst Crush Strength Test Workstation

Keywords:

Category:

Product Description

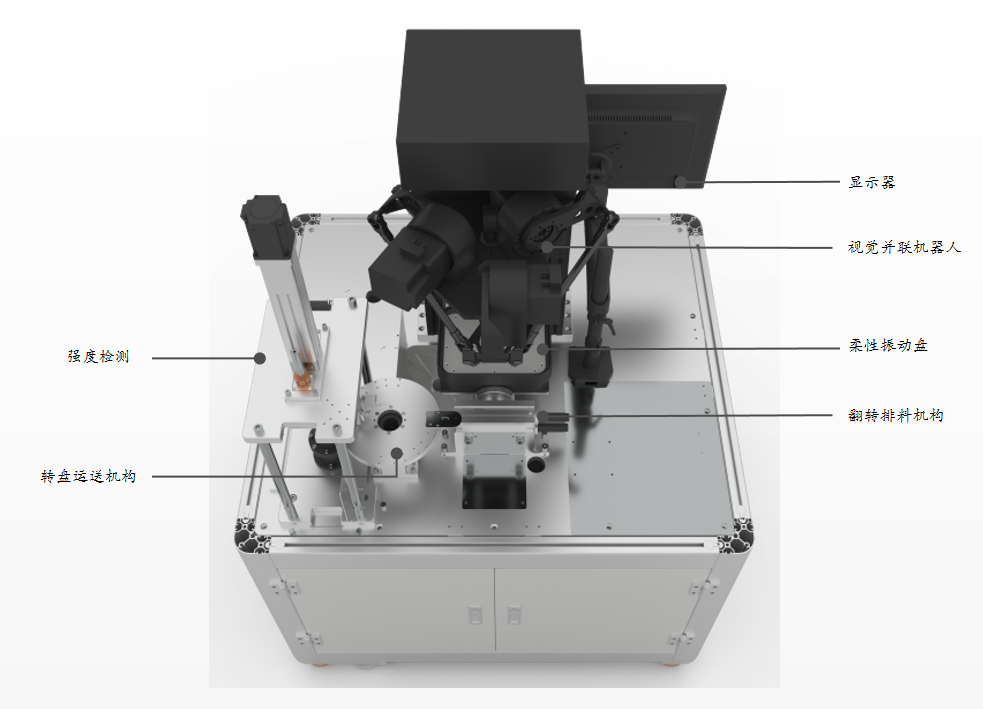

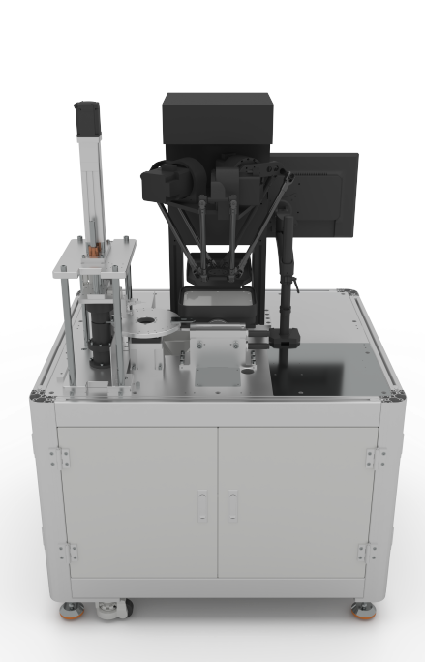

The catalyst crush strength testing workstation integrates parallel robot and visual analysis technologies. This equipment is used for the detection of size and crush strength in catalyst production lines, and it also analyzes the data.

The equipment uses a vision camera to capture and analyze images, automatically identifying the coordinates of the catalyst. A parallel robotic arm automatically grasps the catalyst, performs a secondary inspection of its appearance, and then feeds it into a servo pressure testing device. The computer simultaneously stores the crush data curve for each catalyst.

Main Functions

Catalyst Defect Identification:

- The vision system uses a robot to automatically grasp, identify defects, and perform statistical analysis of the catalyst.

Catalyst Crush Strength Testing:

- Automatically grasps the catalyst, automatically feeds it into the crush strength testing equipment, automatically generates data values, and performs analysis.

Digital Management:

- Real-time monitoring dashboard: current detection data values.

Product Parameters

| Modules |

Core Parameters |

| Parallel Robot | Repeatability: 0.3mm |

| Crusher Module | Pressure: 0-500N, Force Measurement Accuracy: ±0.05%, Pressure Plate Displacement Accuracy: ±0.02mm. |

Product Features:

- Replaces manual testing

- Double Safety Assurance: Emergency stop, physical safety door

- Seamless System Integration: Can be integrated with the enterprise LIMS system

Related Products

Catalyst Crush Strength Test Workstation

The catalyst crush strength testing workstation integrates parallel robot and visual analysis technologies. This equipment is used for the detection of size and crush strength in the catalyst production line, and analyzes the data simultaneously. The equipment uses a vision camera to automatically identify the coordinates of the catalyst. A parallel manipulator automatically grasps the catalyst, performs a secondary inspection of its appearance, and then sends it to a servo pressure testing device. The computer simultaneously stores the crush data curve of each catalyst.

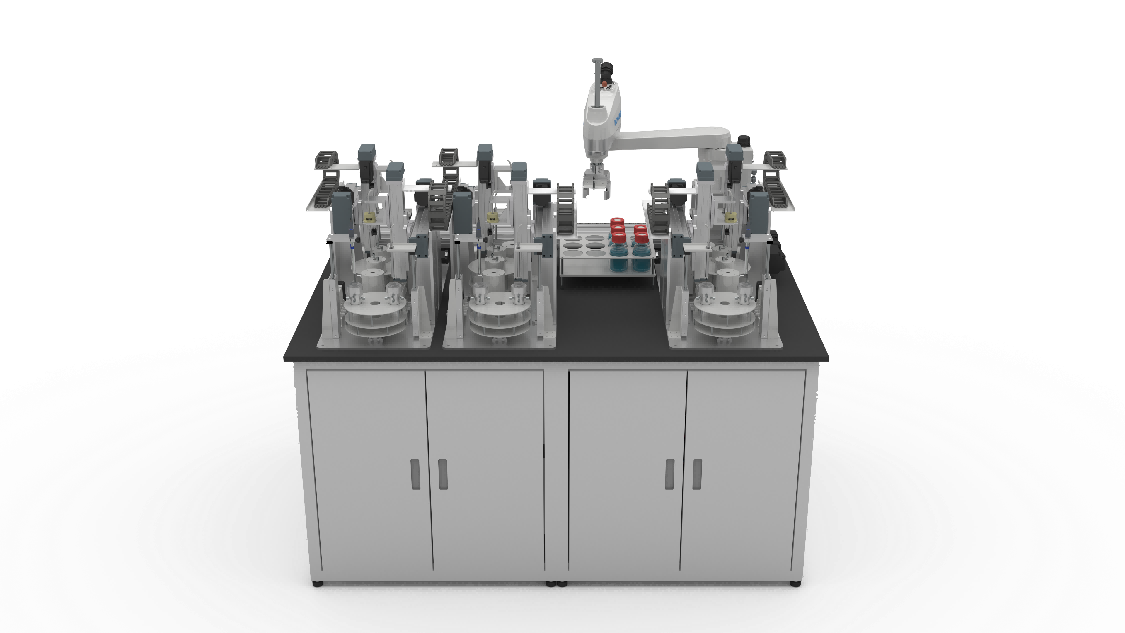

PH automatic analysis workstation

The automated pH analysis workstation integrates collaborative robots, AGV intelligent logistics, and cloud control technology. The workstation uses an advanced automated execution system (such as industrial robots, precision grippers, high-precision diaphragm pumps, servo cylinders, etc.) to achieve unmanned, fully automated pH analysis.

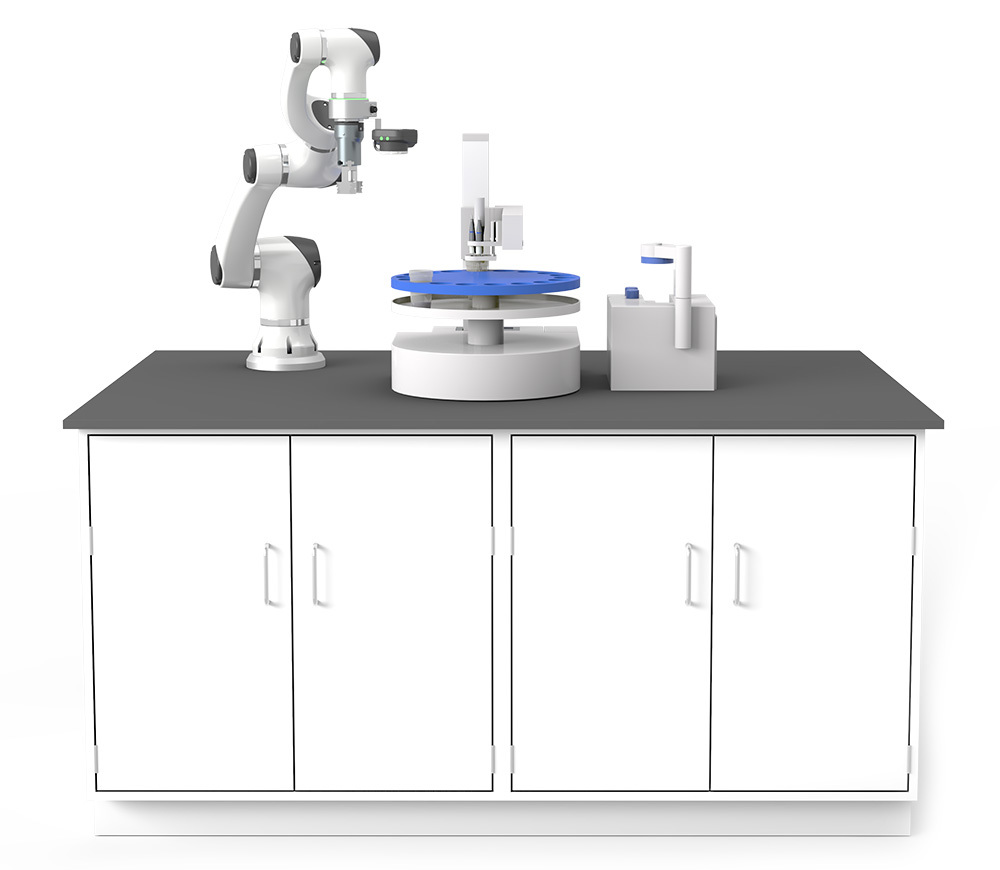

Liquid Precision Weighing Robot DNAW-W600

The liquid precision weighing robot includes a robotic arm, a liquid suction device, a lid-opening manipulator, a precision electronic balance, an ultrasonic distance sensor, and other auxiliary components. It is equipped with intelligent control devices such as an industrial computer, a servo driver, and a small programmable logic controller. It integrates dedicated management software deployed on both the industrial control computer and the user's computer. Users can set the weighing weight and weighing accuracy through the computer, and the robot will automatically complete the weighing work according to the requirements.

Titration automatic detection robot DNAT-W240

The automatic titration detection robot consists of a titration device, a liquid adding device, an automatic sampler robot, etc. The titration device includes a measurement module and interfaces to other units related to titration control; the automatic sampler robot includes an automatic titration manipulator and a sample tray suitable for high-throughput titration applications. The robot, working with a potentiometric titrator, can automatically load and unload samples and complete the entire detection process. The potentiometric titrator can connect to the DynaWise management system to read and upload test data. The automatic titration detection robot can be equipped with various pretreatment modules as needed.

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!